Fast track solution for kzn covid19 wards

Working closely with the Department of Health in Kwa-Zulu Natal, TAL has helped fast track an overhaul of the healthcare facilities at Clairwood Hospital in Mobeni, Durban. Originally converted from army barracks into a hospital in 1956, Clairwood Hospital required significant renovations in order to transform it into a functional modern space that is a key addition to the province's quarantine and isolation centres.

The Clairwood Hospital was under-utilized for the current needs of the province, and rather than making use of temporary mobile hospital units, it was decided to renovate the existing building as a permanent part of Durban’s healthcare infrastructure. This renovation, however, needed to be completed very quickly, in the face of the increasing number of COVID-19 infections in the province. KZN Health MEC Nomagugu Simelane-Zulu said that the COVID-19 facility, which was refurbished in just two months, will enable 154 patients to be isolated and about 40 to be quarantined.

GVK, the main contractor on site, was tasked with gutting the interior walls of the hospital, fitting new partitioning, ceilings and electrics for the new wards across the 4 hospital blocks, with roughly 2 - 3 weeks allocated to complete each block. The site was operational 24 hours a day using two alternating shifts of workers to deliver on the tight project deadlines. Derek Logan Flooring, a TAL registered flooring applicator, stepped up to the challenge of preparing the 1000m2 hospital blocks with a TAL multi-level flooring system, prior to installing Polyflor vinyl sheeting.

As an older building, the surface beds did not have the necessary industry prescribed measures in place to prevent moisture ingress into the building. The flooring system comprised of TAL Vaporstop, a high-density vapour barrier installed across the entire project, providing an impermeable layer to protect the final vinyl floor covering from fluctuating and elevated moisture levels in the substrate. After suitable priming, rapid-setting TAL Screedmaster was used to deliver a smooth and level surface onto which the vinyl sheeting was installed. This product system enabled a fast turnaround time of 48 hours from installation of the vapour barrier to the final floor covering.

Contact the TAL Technical Advisory Service on 0860 000 (TAL) 825 for details and specialist contractors who can apply TAL X-Calibur X-Tech SuperFlow. For more information visit www.x-calibur.co.za and www.tal.co.za

Also ensure that the spacer size you use is correct for the type of tile you have selected; the joint width between glazed ceramic floor tiles should be a minimum of 5mm wide, and a minimum of 3mm wide between porcelain tiles, including rectified porcelain tiles. To achieve the natural look, opt for grout colour that is darker than the tile itself. Click here to find out more about how to select the perfect grout colour.

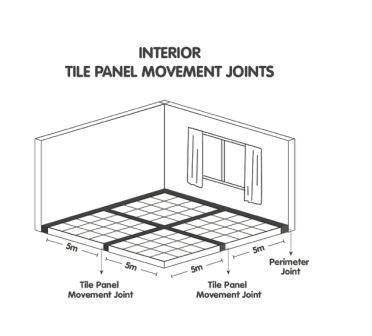

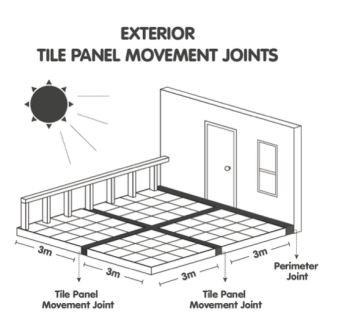

MOVEMENT JOINTS

Allowance for movement (building, thermal and moisture) must be made in all tile installations. Perimeter joints must be installed around the perimeter of all floors and around any fixtures protruding through the tile installation, such as walls, columns and stairs. Intermediate tile panel movement joints should also be installed at maximum 5 metre centres in both directions for interior surface bed applications, and maximum 3 metre centres for suspended slabs and exterior applications. These joints must be a minimum of 5mm wide, must extend through the tile and tile adhesive layers to the substrate, and must be filled with a good quality resilient joint sealant and suitable backing cord.

When using large format tiles (a tile with the length of at least one edge equal to/greater than 600mm, or a facial area greater than 3500cm²) there will be a smaller number of grout joints, compared with the same area of normal format tiling. As a result, less stress (movement) can be accommodated at tile joints.

Considering a wood-look tile installation? Give us a call or send usan email and we’ll give the right advice, no matter how big or small your tile installation: 0860000 TAL (825) or [email protected]. If this TAL Talk blog post interested you, you may want to take a look at this TAL Talk blog post: The 101 on wood-look tiles.

Complete the waterproofing system by replacing the water in the grout mix with TAL Bond, a latex additive, as this further increases the water resistance and flexibility of the installation.

Get the job right the first time and avoid future headaches from water seeping through and damaging the walls and floors of your home. The additional cost and effort of properly waterproofing your shower is an investment in your property and will ensure a beautiful and functional bathroom for years to come.

For more information on multi-level waterproofing systems, contact a TAL Expert on 0860 000 TAL (825), email us or watch our how-to video on YouTube for step-by-step advice on how to waterproof a shower.

STEP 8

Roll the area using a TAL Spiked Roller to facilitate the release of any trapped air to produce a smooth surface, and to allow it to dry.

Allow the screed installation to dry for 24 hours before subjecting to foot traffic (or other trades) or installing floor coverings.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.