TAL stoneflow specified for unique flooring project at Greenstone Shopping Centre

A one-of-a-kind floor designed for the refurbishment of the food court at Greenstone Shopping Centre in Edenvale, Johannesburg, was installed using TAL StoneFlow, a fast track, industrial, terrazzo-look decorative flooring system.

The highly-detailed food court floor, designed by architects Bentel Associates International, entails the transformation of the existing floor into an eye-catching design of large butterflies, ladybirds and dragonflies, using coloured glass aggregates embedded into the seamless, polished screed.

Whilst polished, decorative and seamless concrete floor solutions are in high demand, these terrazzo floors can take up to 28 days to cure before grinding and polishing can commence.

Rapid-setting TAL StoneFlow however, is polishable within four hours of installation, and is designed to produce a durable and hard-wearing surface, which is very well suited for this high foot-traffic area in the shopping centre. Furthermore, the product is shrinkage-compensated, durable and abrasion-resistant, and its seamless, smooth, noise-reducing substrate is easy to maintain. It is especially designed for use in industrial environments, on both new construction and renovation projects. It is designed for applications exposed to heavy traffic and abrasion, such as factories, warehouses and production areas. It is also suitable for commercial and residential applications.

As a cement-based, self-smoothing, heavy-duty decorative screeding system, TAL StoneFlow is available in a wide range of colours and aggregate finish. To achieve the desired aesthetic, the products and aggregates chosen for this project, were manufactured and supplied to specified RAL colours. The unique floor was installed by TAL approved applicator, ThinkFlood Flooring Specialists.

Contact the TAL Technical Advisory Service on 0860 000 TAL (825), to find out more about TAL products, specifications and value-added on-site service offering.

The new floor adhesive is suitably designed for application onto concrete, screed, toppings, and underlayment compounds. Where required, TAL Screedmaster underlayment compound can be installed to achieve the required smooth, level finish suitable for the installation of the covering.

7. WHAT IS THE AVAILABLE PACKAGING QUANTITY AND SHELF LIFE?

TAL Hybridfix is available in a 5 litre, two-component kit, made up of a base and hardener. This product has a shelf life of 6 months from date of manufacture when stored in its original sealed packaging in dry internal conditions between 10°C and 25°C. NB: Never store directly on a concrete floor.

8. IS THIS A TECHNICAL PRODUCT TO APPLY?

Yes. The application of resilient flooring is a skilled operation and should only be carried out by competent and experienced artisans with the correct training and equipment. Application by unskilled labour is not recommended.

APPROXIMATE COVERAGE:

-

Applied by a 1.6mm V-notch Trowel: ± 0.63kg/m2 (10.9m2 per 5L kit)

-

Applied by a 3mm V-notch Trowel: ± 0.98kg/m2 (7.0m2 per 5L kit)

NB: Actual coverages will be determined by substrate porosity, surface profile, workmanship, wastage, etc. Allow additional product (20 – 30%) for highly porous or textured surfaces.

Tools and equipment required:

-

Suitable electronic Moisture Meter

-

Diamond grinder, captive sandblaster, or similar surface preparation equipment.

-

Broom, and heavy-duty vacuum cleaner.

-

Slow speed drill (350 rpm).

-

Approved mixing paddle attachment.

-

1.6mm V-notch trowel for smooth surfaces, and 3mm V-notch trowel for rough surfaces

-

TAL VaporStop HB – moisture/vapour barrier system for substrates with elevated levels of moisture.

The floor must be thoroughly swept to remove all traces of dust and loose particles, taking care to remove the dust rather than redistribute it. (Vacuuming is preferred.) Contamination on the surface will have an adverse effect on both the finish and long-term performance of the floor covering.

9. HOW DO I MIX THE PRODUCT CORRECTLY?

Pre-mix both the base and hardener components to disperse any settlement. Add all of the contents of the hardener component into the base component and mix using a slow speed drill (350 – 500rpm) with an approved mixing paddle attachment for 5 minutes, until both components are fully dispersed, and the mix is uniform in colour and consistency. Be sure to rotate the mixer throughout the container.

Mix only complete full kits. Do not mix up more product than can be used within the pot life (60 minutes @ 23°C).

When using large format tiles (a tile with the length of at least one edge equal to/greater than 600mm, or a facial area greater than 3500cm²) there will be a smaller number of grout joints, compared with the same area of normal format tiling. As a result, less stress (movement) can be accommodated at tile joints.

Considering a wood-look tile installation? Give us a call or send usan email and we’ll give the right advice, no matter how big or small your tile installation: 0860000 TAL (825) or taltech@tal.co.za. If this TAL Talk blog post interested you, you may want to take a look at this TAL Talk blog post: The 101 on wood-look tiles.

HOW DO I APPLY THE PRODUCT?

-

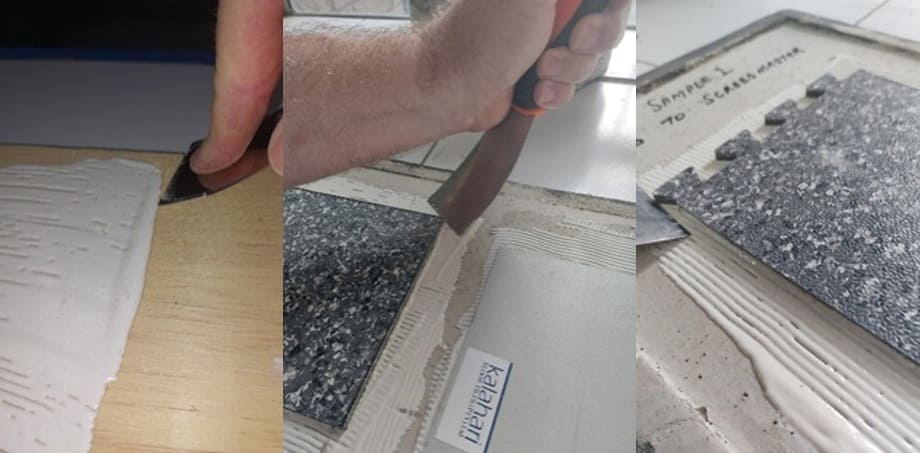

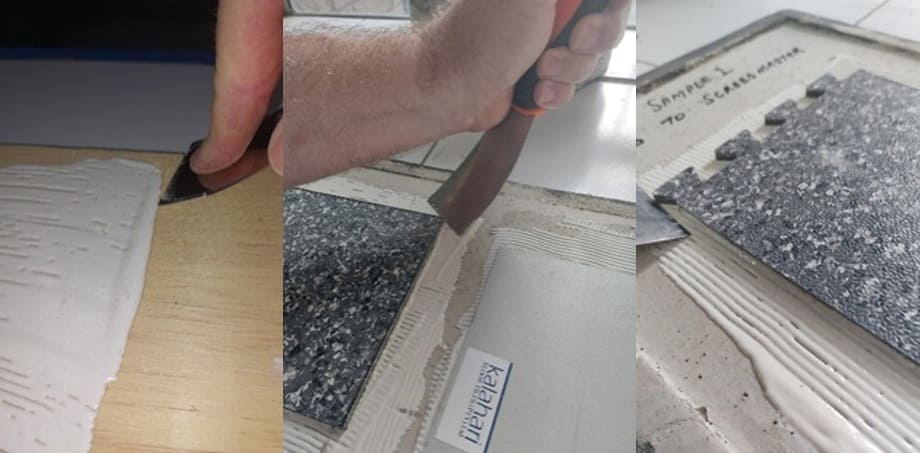

Highly porous woodfloated surfaces must be primed with a “scraper” coat of TAL Hybridfix.

-

This should be applied to the clean, prepared floor substrate using the straight edge of a plastering trowel.

-

-

Once this is done, the next step is to immediately trowel-apply TAL Hybridfix while the “scraper” coat application is still WET.

-

Use the appropriate V-notched trowel, to apply the adhesive onto the clean, prepared substrate.

-

-

Immediately apply the floor covering while the adhesive is still wet.

NB: Do not allow the adhesive to dry, as this will result in an impaired bond.

10. IS THIS PRODUCT QUALITY TESTED?

Yes. All TAL products are manufactured and tested in accordance with TAL procedures, which are maintained in line with Quality Control System Standard ISO 9001, OHSAS 45001and Environmental Management System ISO 14001

CLASSIFICATION ACCORDING TO EN 14259:

TAL Hybridfix exceeds the minimum requirements of EN 14259, for Peel and Shear resistance.

Laboratory Test Data:

|

Appearance |

Pasty |

|

Colour |

Pale Yellow |

|

Density at 20°C |

Grey 1.70 ± 0.02 |

|

Peel (EN 22631/EN 1372) ISO 22631 |

>2.0 N/mm |

|

Application Temperature |

+5° - +35°C |

|

Pot Life* |

Ca 60 minutes |

|

Open Time” |

30 minutes |

|

Cure Time* |

12 hours initial cure. |

|

Shear Resistance (EN 22632/EN1373) |

0.9 N/mm2 |

|

Temperature Resistance |

-15°C - +60°C |

|

Resistance to Dilute Acids & Bases |

Good |

*At 23°C and 50% relative humidity.

The above data was obtained under Laboratory conditions using freshly manufactured material. Actual results in the field will vary as a result of factors such as Ambient Temperatures, Site Conditions, etc.

_______________

For advice or a detailed Materials and Methods Specification, contact the TAL Technical Advice Centre on 0860 000 TAL (825), or e-mail taltech@tal.co.za.

Allow the screed installation to dry for 24 hours before subjecting to foot traffic (or other trades) or installing floor coverings.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email taltech@tal.co.za. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

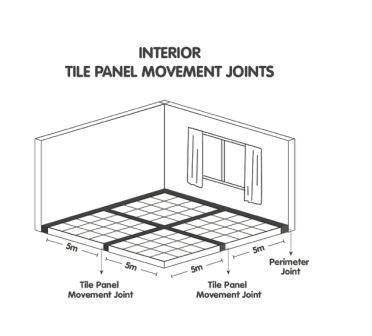

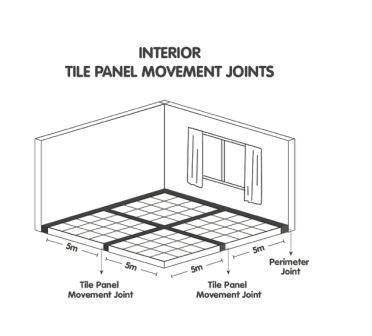

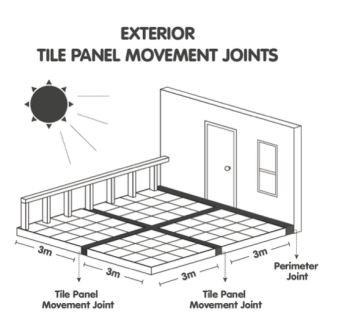

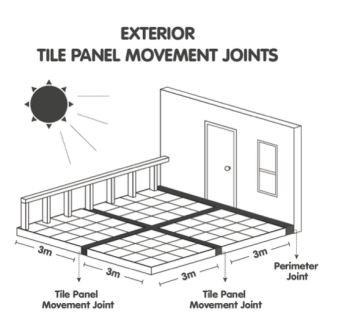

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.