Tiling with natural stone tiles - the basics

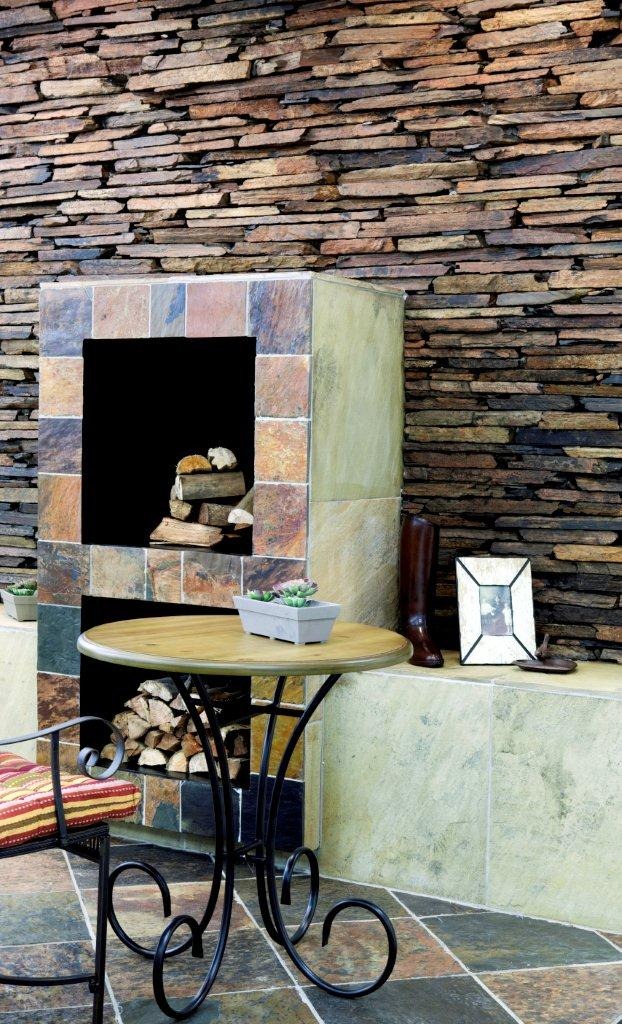

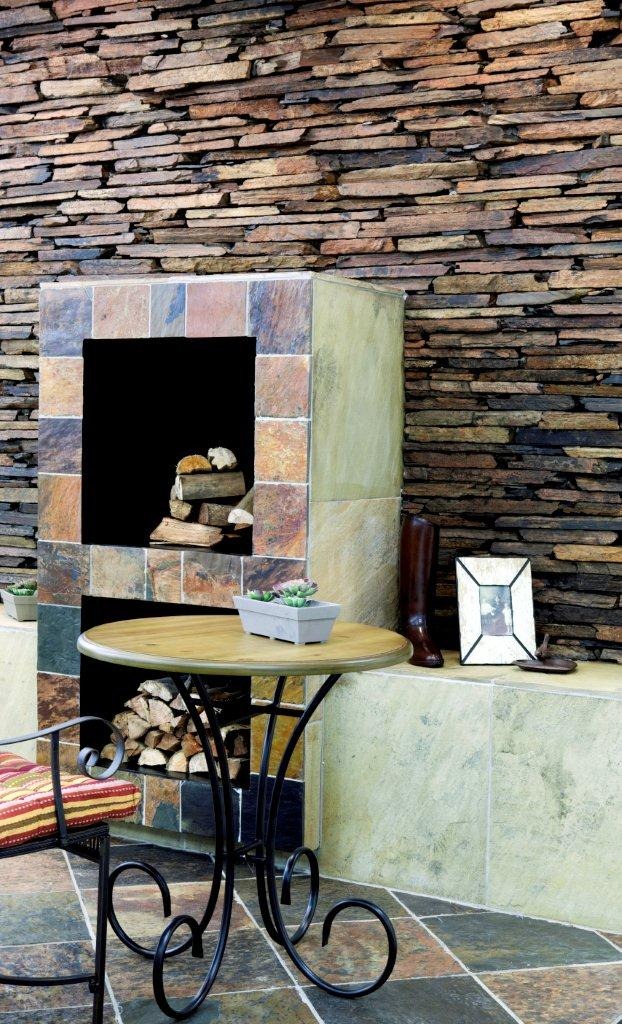

Natural stone tiles are a popular choice for many consumers and rightfully so. They make wonderful features in many different styled homes and interiors. From slate to marble, it seems that natural stone tiles will always be on trend.

Natural stone tiles are made from natural materials such as sandstone, slate, marble and travertine. The stone can be sold in its natural state or it can be polished, which is often the case with marble as this brings out the stone’s colour variations.

One of the major plus points of natural stone tiles is that they can be used for domestic or commercial applications and are ideal for both interior and exterior use. They can also be used on walls or floors and we recommend that they are installed by a tiling contractor.

Natural stone tiles are completely different from machine tiles and can involve much more work. Realising this before installing your natural stone tiles will avoid disaster and is why professional installation is recommended.

One reason for ensuring natural stone tiles are fitted by a professional is that the tiles are usually extremely porous. This means that they will stain unless they are properly sealed. Staining results from water, grout or dirt absorption which will change their appearance. Secondly, their size and thickness might differ slightly from one another since they have not been precisely cut like pressed ceramic tiles. Take this into consideration when laying natural stone tiles.

*Note that real travertine is less robust and not suitable for commercial floors.

INSTALLATION BASICS

- Natural stone tiles show varying mineralogy depending on the source and changing conditions of the particular environment. The use of high-strength, shrinkage-compensated rapid or quick setting adhesives when fixing natural stone tiles are recommended. For dark coloured natural stone tiles, such as slate, sandstone, dark marble and granite we recommend TAL Stonefix. For light coloured marble or natural stone tiles we recommend a light coloured adhesive such as TAL Marblefix or TAL Marbleflex. This is especially important in instances where tiles of varying thicknesses are used, as the adhesive system will have to be built up behind some of the tiles to ensure a level finish.

- The backs of all tiles must be clean and dry and free from dust and contaminants. Natural stone products must also be tested for inherent delamination prior to fixing, particularly when tiling walls.

- Tile panel movement joints must be created at maximum 5 metre centres in both directions for interior surface bed applications and maximum 3 metre centres for suspended applications and exterior applications.

- TAL Stain Free Grout is ideal to use as it is light grey in colour and is specially designed to drastically reduce the staining of highly porous tiles such a sandstone and slate, overcoming the “picture-frame” effect encountered with conventional grout.

- Mix the adhesive and grout with TAL Bond instead of water to enhance strength, flexibility and water resistance.

- Balconies and showers should be waterproofed prior to tiling, using TAL Superflex1 or TAL Sureproof.

- Remember to purchase trims to finish off edges.

- Sealing your tile with the correct product is extremely important. Sealers offer a range of finishes and often enhance the colour/shade of the tile.