Tips for increasing the water resistance of a tiled shower

To ensure a waterproof installation it is essential to waterproof the shower enclosure prior to tiling. However, if an existing tiled shower is showing signs of leaking - i.e. damp patches on adjacent walls or on the ceilings and walls of the levels below - and removing the existing tiles to waterproof and retile the shower is not an option, the following tips should assist in increasing the water resistance of the shower.

INSPECT THE GROUT

-

Water can seep through cracks, voids and even tiny pinholes in the grout joints. If these are detected in the grout, we recommend that the grout be carefully scraped out of the joints, using a grout rake, to a minimum depth of 5mm

-

The joints should then be regrouted, using TAL Wall & Floor Grout mixed with TAL Bond as a total water replacement.

-

TAL Bond is a modified latex additive which will enhance the bond strength, flexibility and water resistance of the grout. Ensure the grout joints are completely filled, and the grout is thoroughly compacted into the joints.

-

Newly installed grout should be allowed to dry for 48 hours before the shower is used. See our infographic on how to revive your grout here.

CHECK THE PERIMETER OF THE SHOWER FLOOR

-

The joint around the perimeter of the shower floor and drain should also be inspected as these are areas where water can permeate through into the tile installation and thus into the substrate. To allow for movement in the tile installations, this joint should be filled with a suitable (shower type) resilient joint sealant. Perhaps the joint was filled with a cementitious grout, or the incorrect type of sealant was used.

If the problem still persists:

-

Provided that the existing tiles are in good condition and firmly attached to the substrate, and of course that the installation allows for added height of new adhesive and tiles, it is possible to waterproof and tile over the existing tiles.

-

Waterproof the shower up to shower rose height, using TAL Superflex or TAL Sureproof waterproofing compounds. See how to waterproof a shower here.

-

Thereafter install the new tiles using a latex-modified adhesive and grout system. TAL Bond should be used as a total water replacement in the adhesive and grout mix to improve the water-resistance of the adhesive and grout.

TAL can issue a Materials and Methods Specification for a tiling installation.

Contact the TAL Technical Advice Centre number on 0860 000 TAL (825) to request a specification.

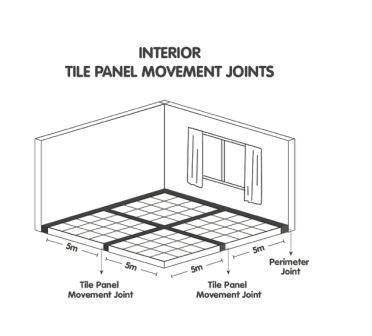

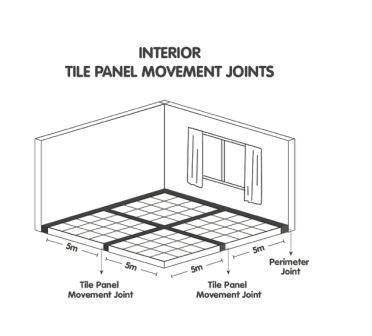

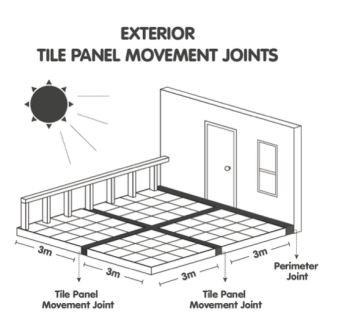

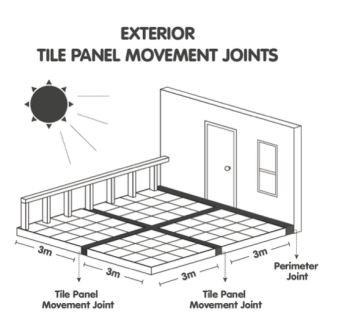

When using large format tiles (a tile with the length of at least one edge equal to/greater than 600mm, or a facial area greater than 3500cm²) there will be a smaller number of grout joints, compared with the same area of normal format tiling. As a result, less stress (movement) can be accommodated at tile joints.

Considering a wood-look tile installation? Give us a call or send usan email and we’ll give the right advice, no matter how big or small your tile installation: 0860000 TAL (825) or [email protected]. If this TAL Talk blog post interested you, you may want to take a look at this TAL Talk blog post: The 101 on wood-look tiles.

Step 4. Bed the mosaics immediately, pressing them firmly into the adhesive. Use a wooden beating block or rubber grouting float to tap them in and create a level surface. Using tile spacers between the individual mosaic sheets will maintain the joints

Step 5. Allow the adhesive to squeeze through the joints between the mosaics to form the grout and, if necessary, fill in any low areas in the joints with extra adhesive.

Step 6. Clean the excess adhesive off the face of the mosaics gently with a lightly dampened sponge, and leave to dry for a few hours.Work carefully to ensure that the mosaic installation is not disturbed, and that the glass mosaics are not scratched during application and cleaning. Polish the mosaic tiles with a dry cloth to remove any grout haze.

Step 7. Apply a silicone sealant to all the perimeter joints.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.