Tools and materials you cant go without when installing mosaics

Tools and Materials You Can’t Go Without When Installing Mosaics

From cheerful and stylish kitchen splashbacks to decorative floor and wall detailing, and even full bathroom floor installations, mosaics are one of the best ways to add colour and interest to drab surfaces around the home. These little tiles (or tesserae, as they are formally known) might be small, but they provide a big impact when installed correctly. And like so much in life, preparation is half the battle. Ensure that you have all the right materials, tools and products on hand before you begin, and you will be well on your way to a successful mosaic installation that will continue to beautify your home for years.

First things first – gather your materials. In the case of a mosaic installation, you will need:

- A Priming System. Surfaces can either be rough or smooth, dense or impervious, and this can make it difficult for the tile adhesive to bond onto the surface. Use our priming guide for more information on what to use for your specific substrate. Remember, if you are installing mosaics in a “wet” area, like your shower, you will need to install a suitable waterproofing system (such as TAL Sureproof) before tiling. See our blog on how to waterproof a shower.

- TAL Mosaicfix. The perfect all-in-one adhesive and grout specially designed for mosaic installations. Available in Super White and Light Grey, TAL Mosaicfix can be used in interior, wet or outdoor areas including showers, kitchens and decorative features. There is no need to purchase additional grout or mix another product, because the bonding and grouting is done in a single operation.

- TAL Bond or TAL Bond Powder. These products are additives that are used as a total water replacement in the mix, or mixed into the water before adding TAL Mosaicfix. This adds bond strength, flexibility and water-resistance to the installation.

Next, it’s time to make sure you have all your tools at hand.

Tiling may look like a simple enough process, but so much of a professional tiler’s secret to success depends on having just the right tools for the job. Here’s everything you will need for every stage of the process, from preparing the substrate to the final cleaning.

Preparing the surface

A flat and level surface is essential for a successful mosaic installation, as any imperfections on the surface can result in an uneven finish. Variations in levels should be corrected before priming.

Mixing the Adhesive

A mechanical mixer is extremely useful for mixing the adhesive quickly and thoroughly. Be sure to use a drill that has at least 1.1kW of power with a suitable mixing paddle.

Installing the mosaics

So much of a mosaic installation’s success is dictated by the spacing between the mosaic sheets, so it’s essential that you use tile spacers to keep it uniform. The size of the spacers must be the same size as the gaps between the individual tesserae on your mosaic sheets for a perfectly uniform finish.

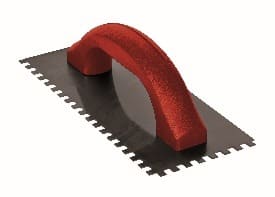

An appropriately notched trowel is indispensable for creating a consistent bed of adhesive, ideally 4mm-6mm for mosaics.

Use a wooden beating block, or a grout float, to press the mosaics firmly into the adhesive. This will promote not only a firm bond, but also a flat surface. Allow the adhesive to squeeze through the joints between the mosaics to create the grout.

Where necessary, use a grout squeegee to apply additional adhesive to fill in any voids in the grout joints.

Keeping it clean

A good quality sponge is your secret weapon to remove excess adhesive from the face of your newly installed mosaics. Use one with rounded edges to prevent grout being gouged out of the joints during cleaning. Ensure the sponge is damp, not wet, as excessive water can affect the performance and integrity of the adhesive, potentially ruining the installation

The bottom line

Mosaics’ small size and wide variety of home applications make them a stylish feature in your home. For the best results, it’s important not to neglect attention to detail, as well as the specialised tools and products that are needed to achieve a beautiful and long-lasting installation.

This is applied using a builder’s block brush and ensuring complete coverage of the existing tiles.

The adhesive can be applied once the slurry priming coat is touch-dry (i.e. no visible transfer when wiped or rubbed).

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.