What to consider when considering underfloor heating

Underfloor heating is a heating solution many home owners and commercial customers are opting for as it is an economical method to heat the floor and ambient temperature of the room.

It is important to select the correct underlayment and to follow the materials and methods specification closely when applying the compound to ensure that the heating system functions at its best.

Underfloor heating systems go hand-in-hand with constant temperature variations caused by the heating cycle. These temperature changes affect the expansion and contraction of the substrate.

To ensure that the underlayment can withstand these temperature shifts and prevent it from cracking, it is important to select the correct cementitious screed and to modify the compound with an additive to provide flexibility to the installation. In addition, the underlayment installation has to adhere to set specifications:

- TAL Superscreed is a high strength, rapid set, non-shrink cementitious screed that produces a smooth hard wearing surface suitable for fixing all floor coverings. It is especially suitable for use as a protective barrier over ceramic tile heating elements, when mixed with TAL Screedbinder.

- TAL Screedbinder is a latex additive that is designed to improve the bond strength and flexibility of the underlayment when used as a total water replacement in the TAL Superscreed mix.

- Apply the levelling compound to the required thickness to completely cover the heating elements and or wires. Often only a couple of millimetres are required. TAL Superscreed can be applied up to 12mm in a single layer.

When tiling in areas with underfloor heating, it is imperative to use a latex-modified adhesive and grout system to allow for the anticipated thermal expansion and contraction.

TAL Bond should be used as a total water replacement in the adhesive and grout mix, and tile panel movement joints should be located at maximum 3 metre centres in both directions, as well as around the perimeter of the floor, or alternatively TAL Bond Powder can be added to the mixing water. Tile panel movement joints should be located at maximum 3 metre centres in both directions, as well as around the perimeter of the floor.

The right choice of underlayment and correct installation method will result in a floor that acts as an efficient heat conductor and therefore improves the energy efficiency of the heating system.

The use of latex-modified adhesive and grout systems will result in a flexible tile installation that can withstand the constant expansion and contraction associated with underfloor heating.

If in doubt, contact the TAL Technical Advice Centre for more information.

The Porcelain Enamel Institute rates abrasion resistance.

PEI SCALE FROM 1 TO 5:

- PEI 1: Domestic/Soft Footwear for Bathrooms and Bedrooms only.

- PEI 2: Domestic/Light Traffic/Interior but exclude Patios, Hallways and Kitchens.

- PEI 3: Domestic/Interior and Exterior includes Patios, Hallways and Kitchens as well as Light Commercial – Flats and Offices.

- PEI 4 for Commercial and Heavy Traffic environments – for retail and hospitals.

- PEI 5: is the ultimate flooring for very Heavy Traffic and Industrial applications including Sports Stadiums and Factories.

When considering porcelain and ceramic tiles, remember that porcelain tiles have much lower water absorption rate than ceramic tiles, which makes them resistant to damage caused by frost.

Article by Richard Nuss

Download tile brochures!

Click here to access our informational electronic brochures on the tiles of your choice.

Find more handy step-by-step guides to assist you with tiling on the DIY tab on TAL’s website: www.tal.co.za

Some of the essential materials required to make the tiling job last include: A primer, such as TAL Keycoat (for mixing a priming slurry with either adhesive or cement), tile adhesive, such as TAL Goldstar 6; grout, such as TAL Wall & Floor Grout or TAL Quarry Grout; a latex additive for the adhesive or grout, such as TAL Bond or clean, cool water if you’re not using a latex additive.

Use a grout such as TAL Wall & Floor Grout for narrow wall and floor grout joints (between 2 and 8mm) and a grout such as TAL Quarry Grout for wider joints (up to 25mm).

High-traffic areas such as the kitchen, passage and entrance halls as well as wet areas such as the bathroom and shower require a water-resistant and flexible tile installation. Replace the water in the cementitious adhesive and grout mixes with a latex additive such as TAL Bond, to improve water resistance, flexibility and bond strength of the mix.

If you’re tackling a renovation project and will be removing broken tiles or replacing existing tiles, consider how you are going to remove the tiles. There are a number of tools that can be used to remove existing tiles:

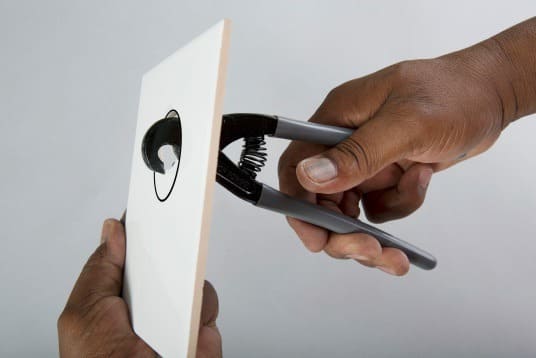

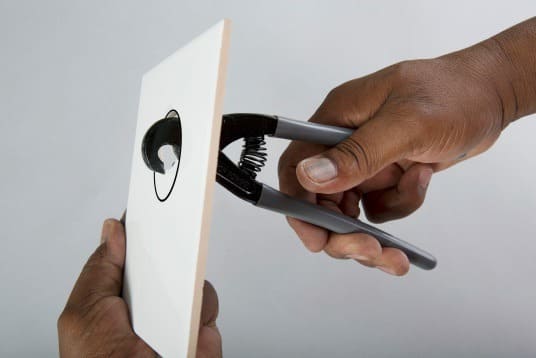

- 3 in 1 Tile Nipper: This multifunctional three-in-one tiling tool is perfect for replacing broken tiles. It consists of a tile nipper with tipped jaws for cutting and shaping wall tiles, a tile pry bar for lifting and re-positioning tiles and a tile breaking chisel for breaking tiles when removing broken tiles.

- Heavy Duty Tile Remover: A professional quality tool which can be used to remove wall and floor tiles as well as carpets and vinyl tiles. This tool is made with reinforced steel and can be used in conjunction with a hammer.

Step 3. Once mixed well, apply the adhesive to the surface in a solid bed of 4 mm to 6 mm, working in small areas of a square metre at a time.

Step 4. Bed the mosaics immediately, pressing them firmly into the adhesive. Use a wooden beating block or rubber grouting float to tap them in and create a level surface. Using tile spacers between the individual mosaic sheets will maintain the joints.

Where necessary, use a grout squeegee to apply additional adhesive to fill in any voids in the grout joints.

Step 5. Allow the adhesive to squeeze through the joints between the mosaics to form the grout and, if necessary, fill in any low areas in the joints with extra adhesive.

Step 6. Clean the excess adhesive off the face of the mosaics gently with a lightly dampened sponge, and leave to dry for a few hours.Work carefully to ensure that the mosaic installation is not disturbed, and that the glass mosaics are not scratched during application and cleaning. Polish the mosaic tiles with a dry cloth to remove any grout haze.

Step 7. Apply a silicone sealant to all the perimeter joints.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.