Calculating tile adhesive

DON’T LET THIS BECOME A STICKY SUBJECT!

Calculating the amount of tile adhesive required for a project is essential to avoid running out of adhesive or having excess material.

TO DETERMINE HOW MUCH TILE ADHESIVE YOU NEED, FOLLOW THESE STEPS!

STEP 1: MEASURE UP!

Square meterage

Begin by calculating the amount of tile adhesive you require for the tile installation project.

- Measure the total area (width and length of the floor or wall) in square meters (m²).

- Refer to the instructions on the product bag for the recommended coverage rate to

calculate how many bags (units of adhesive) you will need.

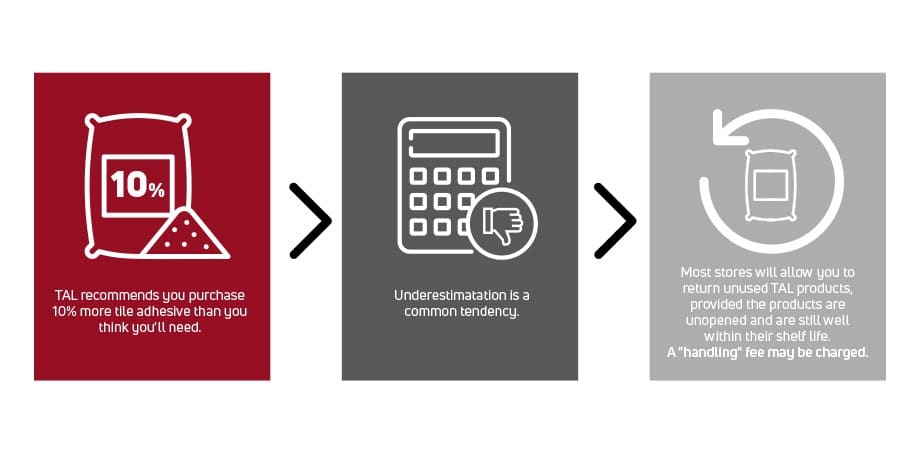

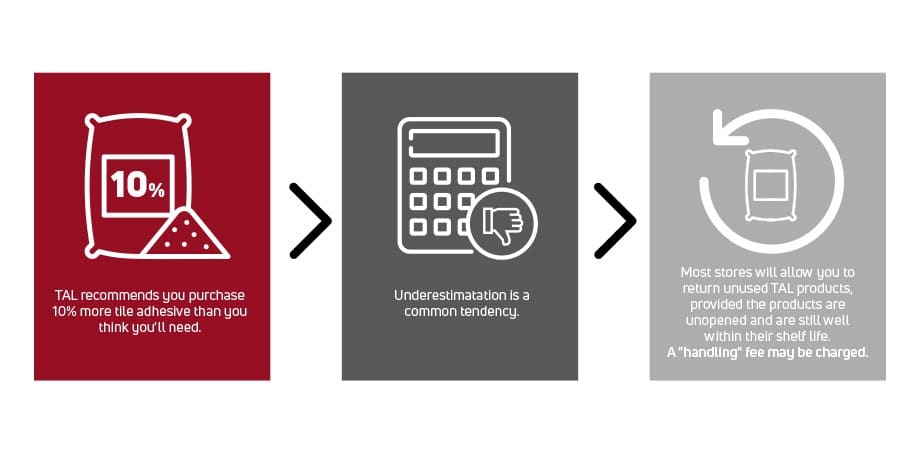

- Add 10% to account for mistakes, waste, or additional tiles.

_________________

IMPORTANT NOTE

- The coverages indicated on the adhesive bags and data sheets are obtained under controlled “ideal” laboratory conditions onto flat/levels surfaces.

- These coverages are intended as a guide for ordering purposes only.

- Site conditions, floor levels, and workmanship affect tile adhesive coverage and quantities – they need to be factored into your calculation!

Now that you’ve estimated the amount of adhesive needed based on the square meterage of the installation area and the manufacturer's recommended coverage rate, proceed to the next step.

STEP 2: CONSIDER OTHER FACTORS!

There are a number of factors that could affect the final calculation of your adhesive requirement:

1. Tile Size:

Begin by determining how many tiles you require. if a single tile is larger than 600 x 600mm, it is considered a large format tile. Due to their size, these tiles may require ‘double trowelling’ of the tile adhesive.

_________________

Double trowelling:

This is when the adhesive is applied onto both the substrate and the back of the tiles, using suitable trowels to ensure full contact and a solid bed of adhesive behind each tile.

Factor this into your calculations.

_________________

2. Substrate levels:

Thicker tile adhesive beds, in isolated areas, may be required to compensate for minor variances in floor levels to achieve a level tiled finish. Working with thicker beds of wet adhesive to compensate for uneven floors is more labour intensive, and this higher adhesive consumption has a cost implication on the installation. The maximum adhesive bed thickness as indicated by the adhesive manufacturer should never be exceeded. Should large variations in levels be found due to the condition of the substrate, these should rather be rectified prior to tiling.

3. Other Factors:

Environmental conditions such as temperature, humidity, and drying time influence adhesive coverage. Tile patterns such as diagonal or herringbone layouts may require more adhesive due to the number of cuts and angles. And workmanship also plays an important role in correct adhesive coverage rate and must be factored in before you order the product.

STEP 3: CHOOSE THE CORRECT TAL ADHESIVE!

All factors considered, be sure to buy the right adhesive for your project.

Click here for a link to TAL’s adhesive range and a guide on which adhesive to use for specific tile installations.

ALWAYS REFER TO THE TAL INSTRUCTIONS ON THE BAG!

Bear in mind that tile adhesive coverage rates can vary depending on factors like trowel notch size, read our blog for more on this topic.

For technical advice please contact our experts on 0860 000 825

or email: [email protected]

When you fully embed the tile into the bed of adhesive, it spreads out the adhesive ridges evenly into the spaces between the trowel lines.

Since the spaces between the ridges have the same size as the ridges themselves, this will split the height of the ridges in half:

-

When held at a 90-degree angle to the substrate, a square notched trowel with 6mm x 6 mm notches should result in a 3mm thick bed of adhesive beneath the tile. The same applies to 10mm x 10mm notches resulting in a 5mm thick bed of adhesive beneath the tile.

-

A 20 x 20mm notched trowel, often referred to as a “thick bed” floor trowel, should result in a 10mm adhesive bed after the tile has been bedded.

-

The more uneven the substrate and the less flat the tile is, the more adhesive you need beneath it, which means a larger trowel size is required.

-

Workmanship also plays a vital role:

- Tiles should be firmly bedded into the adhesive with a “twisting” action to ensure full contact between the adhesive and tiles.

- Tiles should also be well tapped home to ensure they are properly bedded.

-

It is good practice to remove the occasional tile to ensure that good coverage and contact has been achieved. Prominent ridges in the adhesive bed, and minimal adhesive transfer on the tile, after removal is indicative that they were not properly bedded into the adhesive, as the adhesive ridges had not flattened out to fill the valleys left by the trowel application.

_________________

Adhesive coverage depends on a number of factors, including trowel size!

Avoid running out, or having excess material.

Read more in our blog: “Calculating tile adhesive – don’t let this become a sticky subject!”

_________________

BUY THE RIGHT PRODUCT!

Finally, make sure to buy the right adhesive for your project.

Click here for a link to TAL’s adhesive range and a guide on which adhesive to use for specific tile installations.

For technical advice please contact our experts on 0860 000 825

or email: [email protected]

Now, apply the adhesive over a small area using the notched side of a wall trowel to create a solid bed of 4mm to 6mm. Once the adhesive is applied, you must install the mosaic sheets immediately, pressing them firmly into the wet adhesive. Never apply more adhesive than you can tile in 10-15 minutes, usually about a square meter.

Use a wooden beating block or a rubber grout float to embed the mosaic into the adhesive.

Allow the adhesive to squeeze through the joints between the mosaics, to ensure a good bond between adhesive and mosaics, and to form the grout. Place a tile spacer between the countertop and mosaic, as well as between the mosaic sheets, to keep them evenly spaced.

Wait 20 minutes, then, where necessary, fill in any low areas in the grout joints with extra adhesive. TAL Mosaicfix is available in super white and light grey, so choose the colour that will best suit the aesthetic you want to achieve. Work carefully to avoid scratching the tile surface, especially when installing metallic tiles.

Wait 20 minutes, then, where necessary, fill in any low areas in the grout joints with extra adhesive. TAL Mosaicfix is available in super white and light grey, so choose the colour that will best suit the aesthetic you want to achieve. Work carefully to avoid scratching the tile surface, especially when installing metallic tiles.

Once fully set, gently polish the face of the mosaics with a dry cloth

Apply a silicone sealant into the perimeter joint between the mosaics and countertop, and in any corners.

By choosing a kitchen splashback, not only have you managed to successfully upgrade your kitchen into a beautifully modern space, you’ve also ensured that your wall is protected against moisture and food stains. For more information on tile installation, contact the TAL Technical Advisory Service during office hours, visit our website, or send us an email.