How to prime a surface using bitumen adhesive or waterproofing for tile adhesive application

Click here to download TAL’s guide on ‘How to limit the cracking and lifting of tiles’

To prevent cracking and lifting of tiles and the possibility of tiling installation failures, professional and experienced tilers know that special precautions must be taken when tiling the following areas:

-

Where enhanced flexibility is required (Suspended slabs, suspended wooden floors, floors with radiant heating and lift shaft walls)

-

Permanently moist areas (Showers, bathrooms and laundries)

-

Permanently wet areas (Swimming pools)

-

High thermal stress areas (Saunas and steam rooms)

-

External applications exposed to the elements (Patios and balconies)

-

Heavy traffic areas (Car showrooms and factories)

-

Reduced temperature areas (Cold rooms and chiller rooms)

The professional tiler should ensure that the background or surface is properly prepared to accept the tile adhesive by ensuring the surface is firm, sound and dry, free from dust, loose particles, surface contaminants and previous adhesives. The surface may also require priming with a Keycoat Slurry. He should also ensure that there are sufficient tile panel movement joints in the installation to allow for some degree of building and thermal movement. In addition, the tiler would also use a latex based additive in the adhesive and grout to enhance their flexibility, bond strength and water-resistance.

Those familiar with our brand will know TAL Bond, a modified latex liquid additive which is used as a total water replacement in the adhesive or grout mix. These liquids can be heavy and bulky to transport especially for larger installations. Our research and development team, therefore, came up with an alternative additive in the form of a 1kg powder sachet called TAL Bond Powder.

TAL Bond Powder is a special blend of dry-form polymer-based additive and is essentially a concentrated version of the liquid products. Although it is not a latex powder, it fulfils a similar function, but it is considerably easier to handle and transport due to its compact packaging size.

The fundamental difference between these two products is in the mixing. Where TAL Bond liquid is a water replacement, and is poured directly into the mixing bucket before the adhesive or grout powder is added. TAL Bond Powder does, however, require mixing with water to become emulsified before the adhesive or grout powder is added. This extra step is vital as it ensures an even dispersion of the product in the mix. When mixing the following ratios should be followed:

-

20kg tile adhesive or grout should be mixed with 1kg (full sachet) of TAL Bond Powder

-

5kg tile adhesive or grout should be mixed with 500g (half sachet) of TAL Bond Powder

-

2kg tile adhesive or grout should be mixed with 250g (quarter sachet) of TAL Bond Powde

Interested in purchasing TAL Bond Powder? TAL Bond Powder is available from specialist tile retailers such as Tile Africa, tile merchants and large home improvement retailers, such as Builders Warehouse. Give us a call or send us an email and we’ll help you find your nearest stockist: 0860 000 TAL (825) or [email protected]

For more information on TAL’s range of primers and additives, click here. If this TAL Talk post interested you, you may want to take a look at another TAL Talk blog post: Why use a primer and additive in your tiling installation

Step 4. Use a mechanical mixer to mix the ingredients. The slurry must have a smooth, paint-like consistency.

Step 5. Using a builder’s block brush, apply the slurry-mix to the surface, ensuring good coverage, i.e. the slurry coat must fully cover the substrate.

Step 6. Allow the primed area to dry for 4-6 hours before tiling.

Where necessary, use a grout squeegee to apply additional adhesive to fill in any voids in the grout joints.

Complete the waterproofing system by replacing the water in the grout mix with TAL Bond, a latex additive, as this further increases the water resistance and flexibility of the installation.

Get the job right the first time and avoid future headaches from water seeping through and damaging the walls and floors of your home. The additional cost and effort of properly waterproofing your shower is an investment in your property and will ensure a beautiful and functional bathroom for years to come.

For more information on multi-level waterproofing systems, contact a TAL Expert on 0860 000 TAL (825), email us or watch our how-to video on YouTube for step-by-step advice on how to waterproof a shower.

STEP 8

Roll the area using a TAL Spiked Roller to facilitate the release of any trapped air to produce a smooth surface, and to allow it to dry.

Allow the screed installation to dry for 24 hours before subjecting to foot traffic (or other trades) or installing floor coverings.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

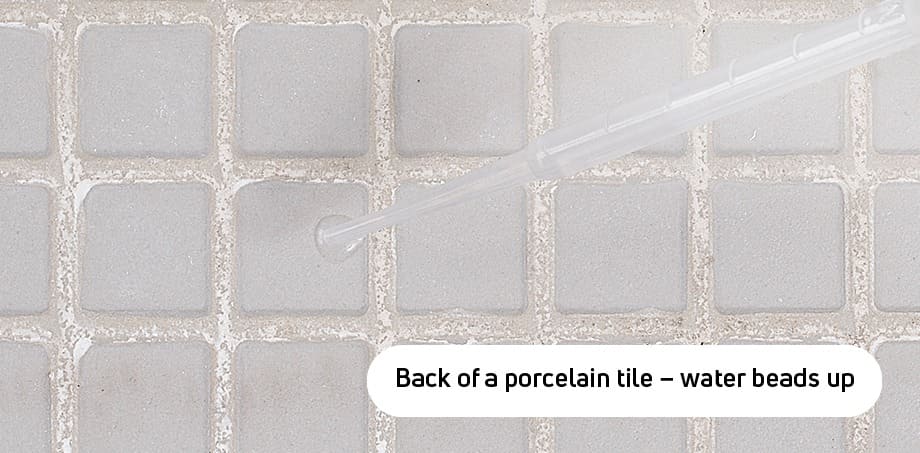

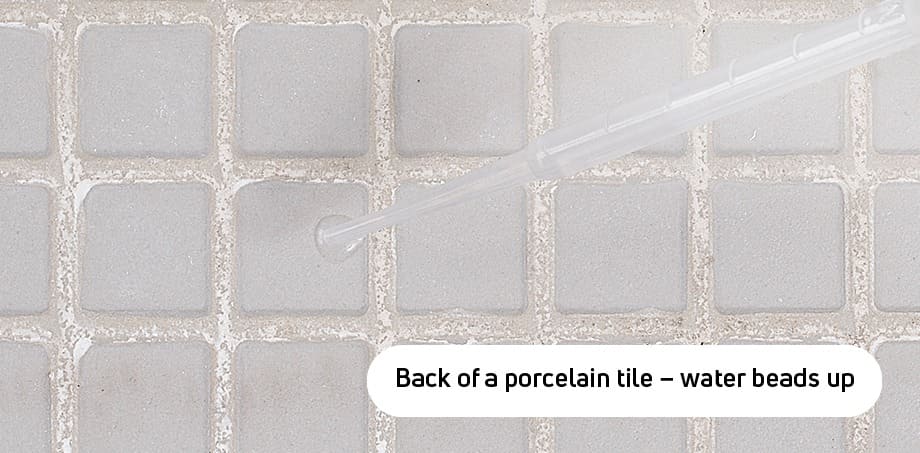

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.