TAL's on-site service offering ensures long-term tile installation success

As part of its value-added service offering, tile and construction adhesives market leader TAL offers comprehensive on-site services.

TAL’s on-site service offering includes product demonstrations, on-site training, site inspections and reporting, and investigations into installation failures. The services are available to professionals such as architects, designers, quantity surveyors and contractors, as well as homeowners completing DIY installations. On-site services are available from project start-up to practical completion.

Tiling and main contractors find on-site services helpful regarding technical issues, mixing of materials, product application, stock requirements and drafting of reports. They also make use of the on-site services in order for TAL to assist them in putting project-specific TAL materials and methods specifications into practice.

This on-site service offering differentiates TAL from the competition. They strongly believe that it is in everyone’s best interest to ensure that tiling installations are undertaken correctly the first time. Remedial tiling, whether caused by incorrect product selection or incorrect installation methods, is not only costly and time-consuming, but also disruptive to the client.

TAL’s commitment and service to the building industry does not end with the sale. They are committed to providing excellent aftersales service. The TAL team boasts extensive knowledge of tiling installation products and processes, and it is their pleasure to assist clients on-site in all practical aspects of a tiling project, to provide them with full peace-of-mind that their tile installation will be a success.

Some of the most common on-site challenges include:

- Tiling onto bitumen

- Waterproofing systems

- Substrates with more movement than anticipated

- Laying down large-format tiles in excess of 1 500 mm x 1 500 mm

- Installing mesh-reinforced natural stone tiles

- Tiling onto uneven substrates

- Tiling onto green concrete or screed

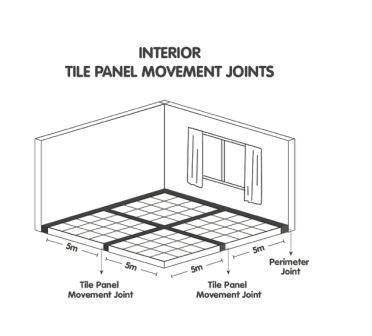

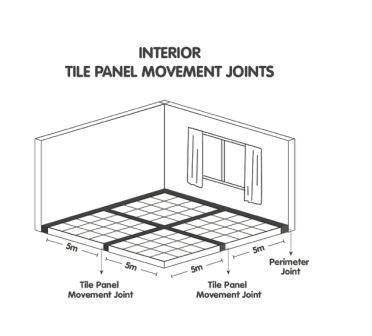

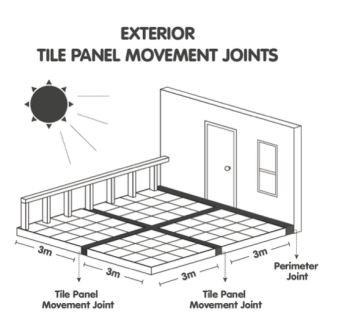

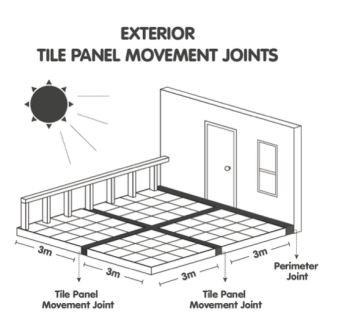

TAL consultants advise on the correct procedures and products to use for the various tiling applications, including curing periods of substrate, background preparation, adhesive and grout systems, and the location of tile panel movement joints. This information is documented in a detailed materials and methods specification, which can be used as a control document for tendering and site purposes.

With a state-of-the-art laboratory and highly-skilled technical staff, TAL is also able to develop laboratory-tested bespoke tiling solutions in the quickest turnaround times. What’s more, TAL offers a ten-year warranty on commercial installations, provided that certain criteria have been met.

TAL also is ISO 9001:2008 quality management system certified and its products are designed, manufactured and tested to TAL standards, thereby assuring clients that products will perform to specification. TAL offers clients an online grout calculator to ensure the greatest project precision, and also features interactive step-by-step guides on the TAL YouTube channel. For a more personalised advice, clients can contact the TAL Advice Centre on 0860 000 TAL (825).

The company indicates that TAL products have been used for the successful installation of tiles at numerous prestigious projects throughout South Africa. With well over 40 years’ experience in the local market, and with over 300 million square metres of tiles successfully installed using TAL products, there simply is no reason to not use TAL products and on-site services.

The new knee pads are available in-store at leading tiling and hardware retailers.

The new range of tile cutters includes manual cutters for the DIY tiler, up to larger models for professional contractors. The Home Tiler’s Manual Tile Cutter is available in 500 mm and 600 mm versions. It features a simple score and snap-cutting action, with a dual chrome-plated, heavy-duty steel rail to ensure smooth scoring.

Larger models are available in a range of sizes to accommodate different size tiles. These are of a heavy-duty design and construction specifically for daily use on-site. Replacement tungsten carbide wheel kits are also available for both the Home Tiler’s and Contractor’s manual tile cutter ranges.

The Professional Contractor’s Heavy Duty Manual Tile Cutter is designed for effortless and accurate cutting of larger-format tiles. Features include a cutting head carriage with ball bearings for high-precision cutting, a balancing arm to support larger tiles during use, and a large graduated swivelling cutting guide. This version is available in 750 mm and 900 mm versions.

The Professional Contractor’s Tile Cutters from TAL are of a heavy-duty design and construction, specifically for daily use on-site.

Due to the temperature fluctuations associated with floor heating systems, add a latex additive like TAL Screedbinder (as a water replacement) to the TAL Superscreed. This is to accommodate the expansion and contraction caused by the heat generated by the elements.

Paying attention to these 4 key points when installing your new carpets will ensure that your investment is long-lasting and adds value to your home.

If you have any questions or are in doubt about how to prepare your floors before installing your chosen final floor covering, call our Technical Advice Centre or send us an email.

When using large format tiles (a tile with the length of at least one edge equal to/greater than 600mm, or a facial area greater than 3500cm²) there will be a smaller number of grout joints, compared with the same area of normal format tiling. As a result, less stress (movement) can be accommodated at tile joints.

Considering a wood-look tile installation? Give us a call or send usan email and we’ll give the right advice, no matter how big or small your tile installation: 0860000 TAL (825) or [email protected]. If this TAL Talk blog post interested you, you may want to take a look at this TAL Talk blog post: The 101 on wood-look tiles.

Complete the waterproofing system by replacing the water in the grout mix with TAL Bond, a latex additive, as this further increases the water resistance and flexibility of the installation.

Get the job right the first time and avoid future headaches from water seeping through and damaging the walls and floors of your home. The additional cost and effort of properly waterproofing your shower is an investment in your property and will ensure a beautiful and functional bathroom for years to come.

For more information on multi-level waterproofing systems, contact a TAL Expert on 0860 000 TAL (825), email us or watch our how-to video on YouTube for step-by-step advice on how to waterproof a shower.

STEP 8

Roll the area using a TAL Spiked Roller to facilitate the release of any trapped air to produce a smooth surface, and to allow it to dry.

Allow the screed installation to dry for 24 hours before subjecting to foot traffic (or other trades) or installing floor coverings.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.