Tal supplies polyurethane flooring solution for spar

TAL recently supplied TAL X-Calibur X-Tech Urafloor HT, a heavy duty, hygienic, polyurethane flooring solution for the Super Spar extension in Avonmore, Durban.

TAL X-Calibur X-Tech Urafloor HT was supplied for the bakery and butchery processing floors where food preparation and cold storage occur. These areas were new additions to the existing building and are approximately 300m² in size. The floor installation was carried out by Durban Tiling.

“The store required a hygienic and easy to clean finish that can withstand the demanding service conditions in its food processing areas,” says Dylan Weweje, sales representative at TAL.

TAL X-Calibur X-Tech Urafloor HT is a heavy duty solvent free, polyurethane flooring system which is available in both screed and self levelling variations. The product is designed to have high abrasion resistance and can withstand chemical attack and thermal shock.

The product is ideal for heavy duty applications in the chemical, cold storage, food and engineering industries. Its primary use is in process areas like the brewing industry, where it can be used as a lining or for bedding applications. TAL X-Calibur X-Tech Urafloor HT is highly durable, is formaldehyde free and provides a seamless and easy to clean finish. The same flooring system was supplied for the Selgro Spar revamp in Pietermaritzburg.

“We manufacture and supply a range of commercial grade polyurethane and epoxy floor coatings as well as chemical resistant linings that are developed to perform in local climate conditions,” he says.

TAL X-Calibur X-Tech Urafloor HT forms part of the TAL X-Calibur range locally manufactured and distributed in sub-Saharan Africa by TAL under license from X-Calibur Construction Chemistry Incorporated.

X-Calibur Construction Chemistry forms part of the TAL building solutions range and consists of construction product solutions with an emphasis on flooring and surface treatments, concrete repair and protection as well as screeds, anchor groutings and fixings, sealers and coatings, floor hardening compounds and waterproofing systems.

TAL is ISO 9001:2008 quality management system certified and its products are designed, manufactured and tested to TAL standards, assuring customers that products will perform to specification.

Contact the TAL Technical Advisory Service on 0860 000 (TAL) 825 or visit www.x-calibur.co.za and www.tal.co.za for more information.

Yet another interesting feature of the show was the way in which lights are being used on surfaces. Lights with LED strips are trending as they are being installed for both aesthetic reasons and to add to the safety aspect of stairs.

Although TAL is constantly reviewing and developing products to suit current requirements, we are particularly interested in looking at ways to improve our offering based on the observations made at Cersaie 2014 – particularly with regards to the large format wood-look tiles.

Also ensure that the spacer size you use is correct for the type of tile you have selected; the joint width between glazed ceramic floor tiles should be a minimum of 5mm wide, and a minimum of 3mm wide between porcelain tiles, including rectified porcelain tiles. To achieve the natural look, opt for grout colour that is darker than the tile itself. Click here to find out more about how to select the perfect grout colour.

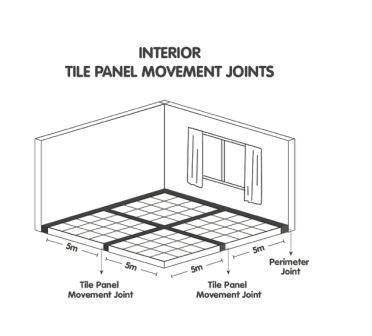

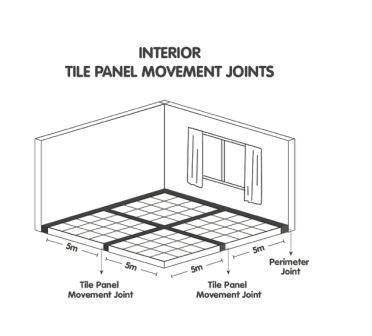

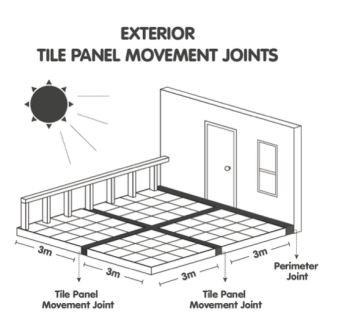

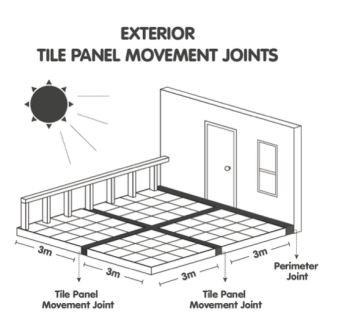

MOVEMENT JOINTS

Allowance for movement (building, thermal and moisture) must be made in all tile installations. Perimeter joints must be installed around the perimeter of all floors and around any fixtures protruding through the tile installation, such as walls, columns and stairs. Intermediate tile panel movement joints should also be installed at maximum 5 metre centres in both directions for interior surface bed applications, and maximum 3 metre centres for suspended slabs and exterior applications. These joints must be a minimum of 5mm wide, must extend through the tile and tile adhesive layers to the substrate, and must be filled with a good quality resilient joint sealant and suitable backing cord.

When using large format tiles (a tile with the length of at least one edge equal to/greater than 600mm, or a facial area greater than 3500cm²) there will be a smaller number of grout joints, compared with the same area of normal format tiling. As a result, less stress (movement) can be accommodated at tile joints.

Considering a wood-look tile installation? Give us a call or send usan email and we’ll give the right advice, no matter how big or small your tile installation: 0860000 TAL (825) or [email protected]. If this TAL Talk blog post interested you, you may want to take a look at this TAL Talk blog post: The 101 on wood-look tiles.

Complete the waterproofing system by replacing the water in the grout mix with TAL Bond, a latex additive, as this further increases the water resistance and flexibility of the installation.

Get the job right the first time and avoid future headaches from water seeping through and damaging the walls and floors of your home. The additional cost and effort of properly waterproofing your shower is an investment in your property and will ensure a beautiful and functional bathroom for years to come.

For more information on multi-level waterproofing systems, contact a TAL Expert on 0860 000 TAL (825), email us or watch our how-to video on YouTube for step-by-step advice on how to waterproof a shower.

STEP 8

Roll the area using a TAL Spiked Roller to facilitate the release of any trapped air to produce a smooth surface, and to allow it to dry.

Allow the screed installation to dry for 24 hours before subjecting to foot traffic (or other trades) or installing floor coverings.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.