Tal supplies rapid-setting and flexible adhesive system for wall and floor tile installations at katherine & west

Katherine & West, an office development on the corner of Katherine and West Streets in the Sandton Gate precinct and TAL supplied ancillary products and adhesives for an installation of porcelain tiles which would fill 10 000m².

The building stands eight stories tall and carries a modern design with its triangular shape, striking glass façade and corner, a prominent black tiled feature wall to which its signage is secured, which faces the intersection of Katherine and West Streets. LYT Architecture designed the building and it was developed by Barrow Properties. It consists of approximately 19 000m² sectional title office space and seven luxury penthouse apartments.

TAL supplied TAL Goldstar 6 adhesive and TAL Bond, a latex additive was used in the installation of tiles on the exterior facade, interior lobby, lift shaft walls, reception area and in the bathrooms. TAL Goldstar 6, being a rapid-setting adhesive, was perfect for a fast-track installation such as this as it allows traffic on the tiled area, depending on site and ambient conditions, after six hours was able to be trafficked after only a few hours, while offering enough flexibility to withstand building and thermal movement and exposure to the elements. Being a grey powder-adhesive, TAL Goldstar 6 is suitable for fixing porcelain, ceramic and dark-coloured granite and marble tiles to walls and floors in interior and exterior installations.

As TAL Fine Epoxy Grout is resistant to most chemicals, it was ideal to use in the applications where hygiene is important – especially in the gym’s change rooms and swimming pools, areas where bacteria and mould growth may commonly occur. As the installation had to be completed within a strict time frame, we supplied TAL Goldstar 6, which allows for full traffic within six hours of the application – should the site and ambient conditions permit. For better substrate adhesion, the surface was coated with TAL Keycoat Primer before the tiling installation started. The project was completed within a nine-month timeframe and the quality of workmanship produced was of the highest standard.

The Professional Contractor’s Heavy Duty Manual Tile Cutter is designed for effortless and accurate cutting of larger-format tiles. Features include a cutting head carriage with ball bearings for high-precision cutting, a balancing arm to support larger tiles during use, and a large graduated swivelling cutting guide. This version is available in 750 mm and 900 mm versions.

The Professional Contractor’s Tile Cutters from TAL are of a heavy-duty design and construction, specifically for daily use on-site.

At TAL, we offer a 10-year warranty on any tiling installation – provided that both the Materials and Methods specifications are strictly followed and that the installation is carried out by a registered TAL tiler, while being monitored by a TAL representative. This is how we ensure that our clients receive a high-quality, lasting installation within the time they have to complete their tiling project.

Paying attention to these 4 key points when installing your new carpets will ensure that your investment is long-lasting and adds value to your home.

If you have any questions or are in doubt about how to prepare your floors before installing your chosen final floor covering, call our Technical Advice Centre or send us an email.

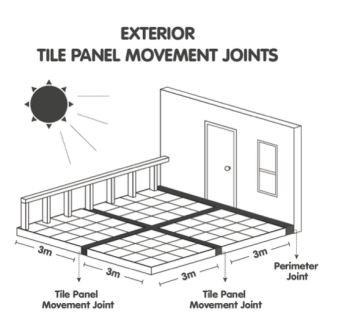

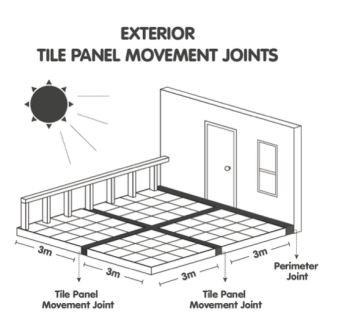

When using large format tiles (a tile with the length of at least one edge equal to/greater than 600mm, or a facial area greater than 3500cm²) there will be a smaller number of grout joints, compared with the same area of normal format tiling. As a result, less stress (movement) can be accommodated at tile joints.

Considering a wood-look tile installation? Give us a call or send usan email and we’ll give the right advice, no matter how big or small your tile installation: 0860000 TAL (825) or [email protected]. If this TAL Talk blog post interested you, you may want to take a look at this TAL Talk blog post: The 101 on wood-look tiles.

Complete the waterproofing system by replacing the water in the grout mix with TAL Bond, a latex additive, as this further increases the water resistance and flexibility of the installation.

Get the job right the first time and avoid future headaches from water seeping through and damaging the walls and floors of your home. The additional cost and effort of properly waterproofing your shower is an investment in your property and will ensure a beautiful and functional bathroom for years to come.

For more information on multi-level waterproofing systems, contact a TAL Expert on 0860 000 TAL (825), email us or watch our how-to video on YouTube for step-by-step advice on how to waterproof a shower.

STEP 8

Roll the area using a TAL Spiked Roller to facilitate the release of any trapped air to produce a smooth surface, and to allow it to dry.

Allow the screed installation to dry for 24 hours before subjecting to foot traffic (or other trades) or installing floor coverings.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

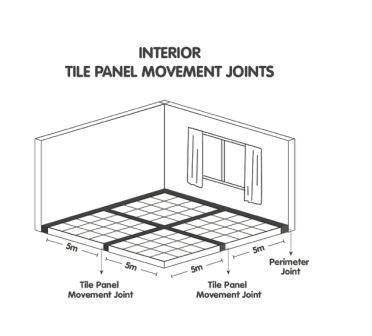

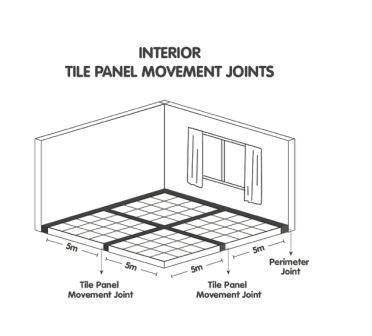

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.