Tips for tiling tricky areas - part 1

Tiling above the bathroom basin and kitchen sink, and around the toilet base, toilet pipe and a light switch can be a bit more difficult.

Here are some easy steps to follow when tiling over a basin and around a toilet base.

Tiling over a basin:

-

- Nail a horizontal batten to get a level starting line corresponding with the first full row of tiles above the basin.

- Tile from this point upwards, using the correct adhesive for the tile selected.

- Once the adhesive has set, remove the batten.

- Cut tiles to accommodate the space between the top of the basin and row of tiles.

- Tile this area, leaving a 5mm joint between the top of the basin and tiles. Fill this joint with a good quality flexible joint sealant, such as TAL Goldstar Sealmaster 1000 polyurethane joint sealant.

Tiling around a curve such as the toilet base:

-

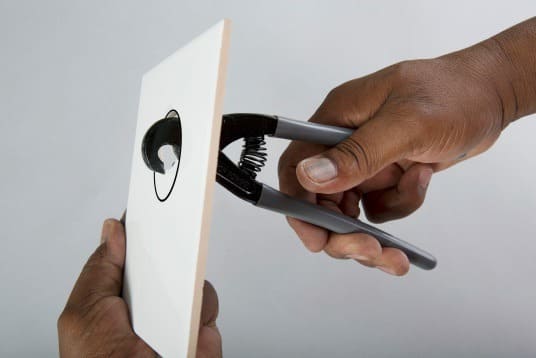

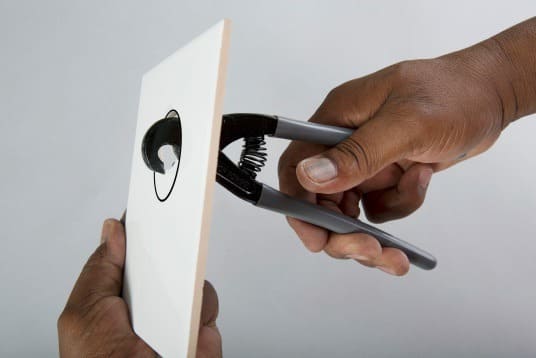

- Measure the curve of the toilet base by using a Tilemate profile gauge. This is a handy tool that assists you to cut a tile in the exact size you need it to be to ensure your tiling job looks perfect. It follows the curvature of an object, such as the semicircle at the foot of the toilet, and allows for precise measurement.

- Transfer the curve measurement onto the tile or tiles.

- Once the tiles have been cut to accommodate the curve of the base of the toilet, the actual tile installation will proceed as per normal floor tiling.

- Use the correct adhesive for the tile selected and leave a 5mm joint between the tiles and the base of the toilet.

- Fill this joint with a good quality flexible joint sealant, such as TAL Goldstar Sealmaster 1000 polyurethane joint sealant.

Be sure to visit the DIY tab on the TAL website where you’ll find more useful tips and step-by-step guides on tiling.

Some of the essential materials required to make the tiling job last include: A primer, such as TAL Keycoat (for mixing a priming slurry with either adhesive or cement), tile adhesive, such as TAL Goldstar 6; grout, such as TAL Wall & Floor Grout or TAL Quarry Grout; a latex additive for the adhesive or grout, such as TAL Bond or clean, cool water if you’re not using a latex additive.

Use a grout such as TAL Wall & Floor Grout for narrow wall and floor grout joints (between 2 and 8mm) and a grout such as TAL Quarry Grout for wider joints (up to 25mm).

High-traffic areas such as the kitchen, passage and entrance halls as well as wet areas such as the bathroom and shower require a water-resistant and flexible tile installation. Replace the water in the cementitious adhesive and grout mixes with a latex additive such as TAL Bond, to improve water resistance, flexibility and bond strength of the mix.

If you’re tackling a renovation project and will be removing broken tiles or replacing existing tiles, consider how you are going to remove the tiles. There are a number of tools that can be used to remove existing tiles:

- 3 in 1 Tile Nipper: This multifunctional three-in-one tiling tool is perfect for replacing broken tiles. It consists of a tile nipper with tipped jaws for cutting and shaping wall tiles, a tile pry bar for lifting and re-positioning tiles and a tile breaking chisel for breaking tiles when removing broken tiles.

- Heavy Duty Tile Remover: A professional quality tool which can be used to remove wall and floor tiles as well as carpets and vinyl tiles. This tool is made with reinforced steel and can be used in conjunction with a hammer.

Step 3. Once mixed well, apply the adhesive to the surface in a solid bed of 4 mm to 6 mm, working in small areas of a square metre at a time.

Step 4. Bed the mosaics immediately, pressing them firmly into the adhesive. Use a wooden beating block or rubber grouting float to tap them in and create a level surface. Using tile spacers between the individual mosaic sheets will maintain the joints.

Where necessary, use a grout squeegee to apply additional adhesive to fill in any voids in the grout joints.

Step 5. Allow the adhesive to squeeze through the joints between the mosaics to form the grout and, if necessary, fill in any low areas in the joints with extra adhesive.

Step 6. Clean the excess adhesive off the face of the mosaics gently with a lightly dampened sponge, and leave to dry for a few hours.Work carefully to ensure that the mosaic installation is not disturbed, and that the glass mosaics are not scratched during application and cleaning. Polish the mosaic tiles with a dry cloth to remove any grout haze.

Step 7. Apply a silicone sealant to all the perimeter joints.

TAL MOSAICFIX is available in 20 kg and 5 kg bags from leading retail outlets.

Designed to be 100% compatible, using the TAL range of products ensures fully guaranteed multi-level tiling systems from a single source. TAL products are manufactured in South Africa to suit local climatic conditions.

If you are in any doubt, contact the TAL Technical Advisory Service on 0860 000 TAL (825), email [email protected]. Alternatively, employ the services of an experienced and skilled mosaic tiling contractor.

When replacing tiles, it is not always possible to apply the TALFIX directly to the floor, in which case apply the adhesive in a solid bed onto the back of the tile, ensuring complete coverage. Gently trace the notched side of a floor trowel through the adhesive to create ‘ridges’.

Adhesive system

When tiling onto existing tiles, it is important to only use a quick- or rapid-setting adhesive, as the existing tiles will present a dense, impervious surface, and standard-setting adhesives will take longer to dry. Too early trafficking of newly-installed tiles before the adhesive has set sufficiently can result in hollow-sounding or loose tiles.

Use TAL Tile-To-Tile quick-setting adhesive for tiling onto interior surface beds. When tiling onto suspended slabs and for external installations mix the TAL Tile-To-Tile with TAL Bond, replacing the water in the mix. Alternatively, TAL Bond Powder can be added to the adhesive mixing water.

Ensure that there is a solid bed of adhesive at least 6 mm thick beneath each tile.

Back buttering with a thin coat of adhesive may also be required when using large-format tiles to ensure full contact with the adhesive bed.

Grouting

Grouting should not be carried out until the adhesive has set sufficiently to prevent the tile installation from being disturbed during the grouting operation (always refer to the adhesive packaging for setting times). When using TAL TAL Tile-To-Tile, allow a minimum of six hours before grouting.

For interior surface beds, use TAL Wall & Floor Grout for filling tile joints up to 8 mm wide. TAL Quarry Grout can be used in wider joints up to 25 mm wide. On suspended slabs and for external installations, replace the water in the grout mix with TAL Bond, or add TAL Bond Powder to the grout mixing water.

Particular care must be taken to clean the grout off the tile face before it hardens completely. This is especially important when an additive such as TAL Bond or TAL Bond Powder has been used. A tile sample should be tested beforehand to ensure that no grout is absorbed through the glaze or into the tile body, thereby staining the tiles permanently.

Movement joints

The lack of movement joints in tile installations is a major cause of tile failure. When tiling over existing tiles, the existing structural and movement joints must be maintained in the new tile installation. The movement joints should be at least 5 mm wide and extend through the adhesive and both tile layers.