TAL HYBRIDFIX

10 common questions about why our new floor tile adhesive gives you a watertight fix in high-traffic areas!

Hybrid cars, hybrid work hours, and now hybrid floor tile adhesive! TAL has a reputation for pioneering every type of floor tile fixing adhesive in the local market! The introduction of TAL Hybridfix is our latest fit-for-purpose tiling installation solution, specially formulated as a fixative for specialized, resilient PVC composite flooring.

1. WHY IS THIS A HYBRID PRODUCT?

TAL Hybridfix is a hybrid adhesive made up of two components:

-

rigid polyurethane and,

-

an epoxy-base

These two components give TAL Hybridfix enhanced substrate moisture tolerance.

2. WHICH SURFACES DO I APPLY TAL HYBRIDFIX TO?

This specialized floor tile adhesive is formulated specifically for the installation of composite vinyl interlocking tile flooring. This resilient PVC flooring type is typically used to create the smooth, seamless floors found in high-traffic areas such as supermarkets.

3. WHAT PROBLEM DOES IT SOLVE?

A common problem when composite PVC vinyl interlocking tile flooring is installed, is that some tiles may lift or peak in moisture-exposed areas, for example, near refrigeration units or entrances. TAL Hybridfix adhesive seals the surface beneath and between tiles. Once cured, it becomes rock hard and watertight, preventing moisture build-up; essentially sealing tile ridges during installation when the tiles are knocked into place.

4. HOW LONG DOES IT TAKE TO CURE?

TAL Hybridfix is rapid setting, with an initial cure time of 12 hours (@ 20°C). While it is advisable to wait a minimum of 12 hours before exposure to light foot traffic, 24 hours should be factored in before exposure to full-service conditions (depending on site and ambient conditions). Allow a minimum of 7 days before exposure to water/cleaning procedures.

NB: Due to the temperature-sensitive nature of resin-based compounds, should this installation be undertaken during the winter months, longer drying/curing times should be anticipated and catered for.

5. DOES TAL HYBRIDFIX HAVE ANY ADVANCED FEATURES?

6. WHAT ARE THE IDEAL AREAS OF APPLICATION?

-

Commercial and retail flooring: supermarkets, shopping malls, retail stores, and commercial spaces.

-

Healthcare facilities: hospitals, clinics, and laboratories where hygiene and durability are essential for flooring.

-

Educational institutions: Use in schools, colleges, and universities for flooring in corridors, classrooms, and common areas.

-

Sports facilities: Flooring in gyms, sports turfs.

The new floor adhesive is suitably designed for application onto concrete, screed, toppings, and underlayment compounds. Where required, TAL Screedmaster underlayment compound can be installed to achieve the required smooth, level finish suitable for the installation of the covering.

7. WHAT IS THE AVAILABLE PACKAGING QUANTITY AND SHELF LIFE?

TAL Hybridfix is available in a 5 litre, two-component kit, made up of a base and hardener. This product has a shelf life of 6 months from date of manufacture when stored in its original sealed packaging in dry internal conditions between 10°C and 25°C. NB: Never store directly on a concrete floor.

8. IS THIS A TECHNICAL PRODUCT TO APPLY?

Yes. The application of resilient flooring is a skilled operation and should only be carried out by competent and experienced artisans with the correct training and equipment. Application by unskilled labour is not recommended.

Approximate Coverage:

-

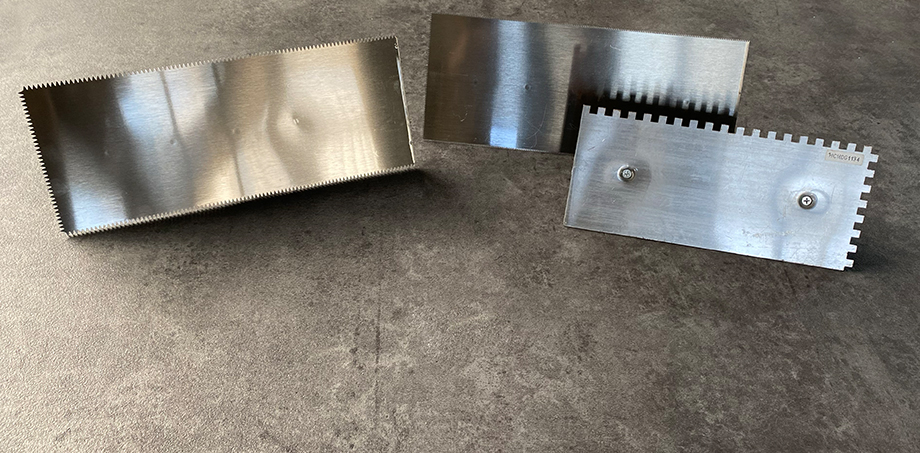

Applied by a 1.6mm V-notch Trowel: ± 0.63kg/m2 (10.9m2 per 5L kit)

-

Applied by a 3mm V-notch Trowel: ± 0.98kg/m2 (7.0m2 per 5L kit)

NB: Actual coverages will be determined by substrate porosity, surface profile, workmanship, wastage, etc. Allow additional product (20 – 30%) for highly porous or textured surfaces.

Tools and equipment required:

-

Suitable electronic Moisture Meter

-

Diamond grinder, captive sandblaster, or similar surface preparation equipment.

-

Broom, and heavy-duty vacuum cleaner.

-

Slow speed drill (350 rpm).

-

Approved mixing paddle attachment.

-

1.6mm V-notch trowel for smooth surfaces, and 3mm V-notch trowel for rough surfaces

-

TAL VaporStop HB – moisture/vapour barrier system for substrates with elevated levels of moisture.

The floor must be thoroughly swept to remove all traces of dust and loose particles, taking care to remove the dust rather than redistribute it. (Vacuuming is preferred.) Contamination on the surface will have an adverse effect on both the finish and long-term performance of the floor covering.

9. HOW DO I MIX THE PRODUCT CORRECTLY?

Pre-mix both the base and hardener components to disperse any settlement. Add all of the contents of the hardener component into the base component and mix using a slow speed drill (350 – 500rpm) with an approved mixing paddle attachment for 5 minutes, until both components are fully dispersed, and the mix is uniform in colour and consistency. Be sure to rotate the mixer throughout the container.

Mix only complete full kits. Do not mix up more product than can be used within the pot life (60 minutes @ 23°C).

HOW DO I APPLY THE PRODUCT?

-

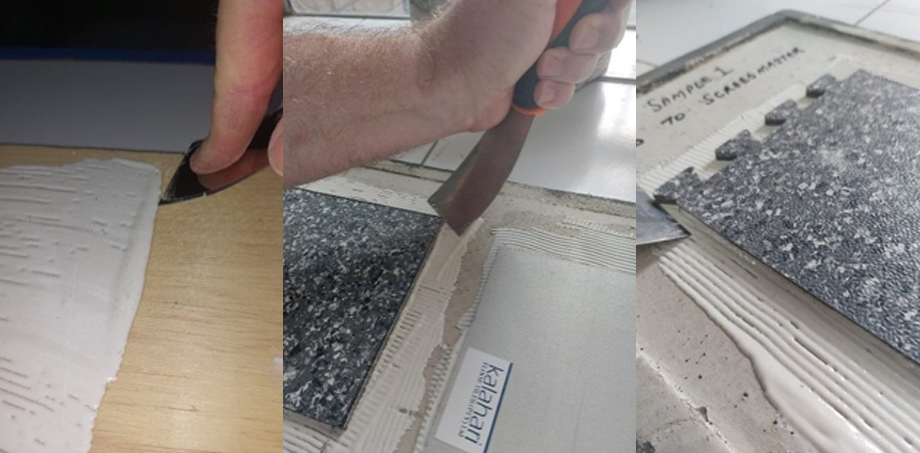

Highly porous woodfloated surfaces must be primed with a “scraper” coat of TAL Hybridfix.

-

This should be applied to the clean, prepared floor substrate using the straight edge of a plastering trowel.

-

-

Once this is done, the next step is to immediately trowel-apply TAL Hybridfix while the “scraper” coat application is still WET.

-

Use the appropriate V-notched trowel, to apply the adhesive onto the clean, prepared substrate.

-

-

Immediately apply the floor covering while the adhesive is still wet.

NB: Do not allow the adhesive to dry, as this will result in an impaired bond.

10. IS THIS PRODUCT QUALITY TESTED?

Yes. All TAL products are manufactured and tested in accordance with TAL procedures, which are maintained in line with Quality Control System Standard ISO 9001, OHSAS 45001and Environmental Management System ISO 14001

Classification according to EN 14259:

TAL Hybridfix exceeds the minimum requirements of EN 14259, for Peel and Shear resistance.

Laboratory Test Data:

|

Appearance |

Pasty |

|

Colour |

Pale Yellow |

|

Density at 20°C |

Grey 1.70 ± 0.02 |

|

Peel (EN 22631/EN 1372) ISO 22631 |

>2.0 N/mm |

|

Application Temperature |

+5° - +35°C |

|

Pot Life* |

Ca 60 minutes |

|

Open Time” |

30 minutes |

|

Cure Time* |

12 hours initial cure. |

|

Shear Resistance (EN 22632/EN1373) |

0.9 N/mm2 |

|

Temperature Resistance |

-15°C - +60°C |

|

Resistance to Dilute Acids & Bases |

Good |

*At 23°C and 50% relative humidity.

The above data was obtained under Laboratory conditions using freshly manufactured material. Actual results in the field will vary as a result of factors such as Ambient Temperatures, Site Conditions, etc.

_______________

For advice or a detailed Materials and Methods Specification, contact the TAL Technical Advice Centre on 0860 000 TAL (825), or e-mail taltech@tal.co.za.

Branches: Gauteng (011) 206-9700; Cape (021) 386-1810; Natal (031) 579-2263

[Back]

blog comments powered by Disqus